Traditional manufacturing jobs are rapidly disappearing worldwide.

Although, the manufacturing industry as a whole is projected to shrink by 0.5% there are hundreds of thousands of in-demand manufacturing jobs that will need to be filled by 2028.

Lower-skilled workers in emerging markets and developing economies are bypassing manufacturing jobs as they shift from agriculture to services occupations.

While in advanced economies, such as the United States, the disappearance of manufacturing jobs has been accompanied by a rise in service sector employment.

These shifts in economic activity are part of the natural structural transformation process of an advanced economy. The more money people make, the more services they consume, particularly within healthcare and finances.

Additionally, technological advances have led to sizable labor savings. Allowing manufacturers to still achieve or exceed previous production numbers with fewer workers.

This is especially true in regions that developed as manufacturing hubs, particularly in the Midwest and Rust Belt.

This is where low to middle-skilled workers are the most impacted by the disappearing of manufacturing jobs.

Across the country, production workers make 20% below the national average, and one-third of all manufacturing workers rely on food stamps and/or other federal assistance programs to survive.

Although, manufacturing jobs have increased in the Sun Belt and Silicon Valley. These newer production jobs are lower-paying, non-union jobs.

Resulting in lost wages for Americans without college degrees – much of whom comprise the manufacturing workforce.

Therefore, new policies should focus on revitalizing the workers America has neglected for two decades.

The government should incentivize employers for implementing structured on-the-job-training and apprenticeship programs.

While investing aggressively in infrastructure with policies that don’t devalue our currency.

If implemented properly, these policies would create more demand for not only manufacturing workers but trade, transportation, and utility workers as well. All of which creates the backbone of our great nation.

While companies should invest in new training technologies that focus on upskilling employees to meet changing workforce and production demands.

On-the-job training is economical, simple, and effective, and can be implemented by companies both large and small.

It doesn’t require wide-ranging budgets, complex training courses, devoted training staff, or absence from the workplace.

All it requires is a commitment to engaging and upskilling employees to efficiently meet production demands with a strategically structured approach.

Doing so will yield impressive results and add value to the American economy.

As part of our mission to bridge the gap between career seekers and employers from coast-to-coast, we’re shining our OJT spotlight on the Manufacturing industry.

So we’ve compiled a comprehensive list of the Top 10 Most In-Demand Manufacturing Jobs.

Each of our most in-demand manufacturing jobs is accompanied by some quick facts, including employment projections through 2028, to help job seekers jump start their search.

Some of the jobs featured on this list are projected to lose jobs over the next 8-years. However, these jobs are a small fraction of the total number of jobs.

Enjoy!

Top 10 Most In-Demand Manufacturing Jobs

Hand Laborers and Material Movers manually move freight, stock, or other materials, packing and wrapping them by hand. Moving materials to and from storage and production areas, loading docks, delivery trucks, ships, and containers. Some workers retrieve products from storage and move them to loading areas. Other workers load and unload cargo from a truck. Keeping detailed records of the material they move to ensure proper delivery. The largest employer of hand laborers & material movers is transportation and warehousing companies.

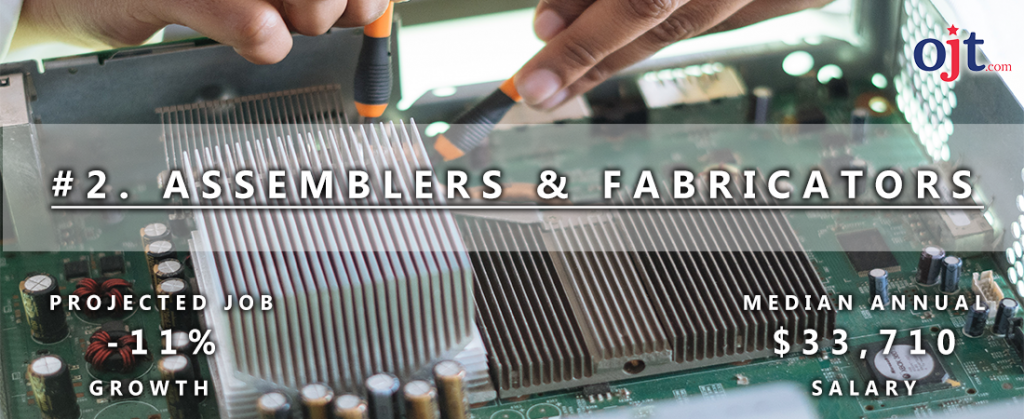

Assemblers and Fabricators assemble complex finished products and the parts that go into them. Using tools, machines, and their hands to make engines, computers, aircraft, ships, boats, toys, electronic devices, control panels, and more. Reading and understanding blueprints and schematics are extremely important in this role. The largest employer of assemblers & fabricators is transportation equipment manufacturers.

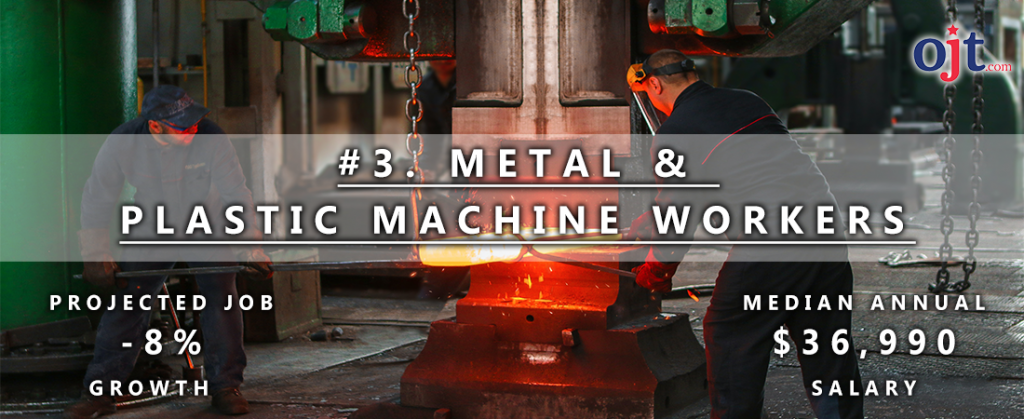

Metal & Plastic Machine Workers set up and operate machines that cut, shape, and form metal and plastic materials or pieces. The setup machines before production, performing test runs, and making adjustments. They then load the machine with materials for production, monitoring, and adjusting the machine’s speeds during production. Reading and understanding blueprints and schematics are extremely important in this role. The largest employer of metal & plastic machine workers is fabricated metal product manufacturers.

Quality Control Inspectors assemble complex finished products and the parts that go into them. Using tools, machines, and their hands to make engines, computers, aircraft, ships, boats, toys, electronic devices, control panels, and more. Reading and understanding blueprints and schematics are extremely important in this role. The largest employer of quality control inspectors is manufacturers.

Machinists & Tool & Die Makers set up, operate, and disassemble manual, automatic, and computer numerically controlled (CNC) machine tools. Aligning, securing, and adjusting cutting tools and workpieces. Monitoring the feed and speed of machines, and testing completed products for defects. Reading and understanding blueprints, schematics, and CAD files are extremely important in this role. The largest employer of machinists & tool & die Makers is manufacturers.

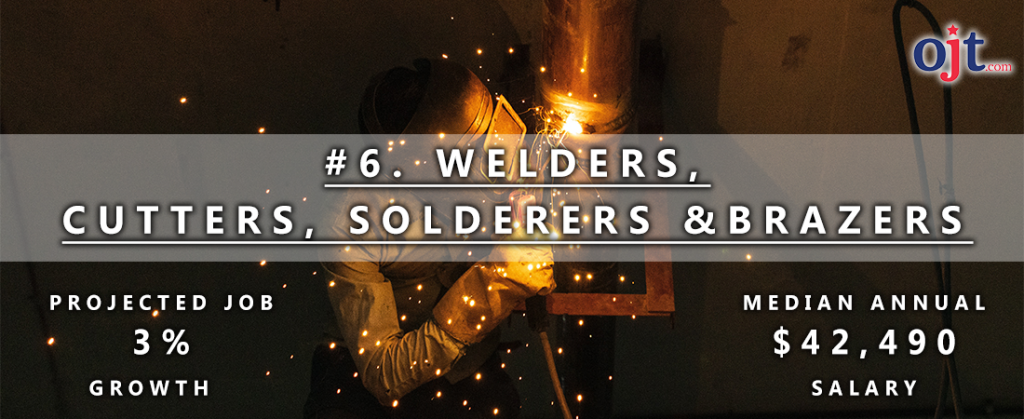

Welders, Cutters, Solderers, and Brazers use hand-held or remotely controlled equipment to join or cut metal parts. They also fill holes, indentations, or seams in metal products. Welding is the most common way of permanently joining metal parts. In this process, heat is applied to metal pieces, melting and fusing them to form a permanent bond. Reading and understanding blueprints and schematics are extremely important in this role. The largest employer of welders, cutters, solderers, and brazers are manufacturers.

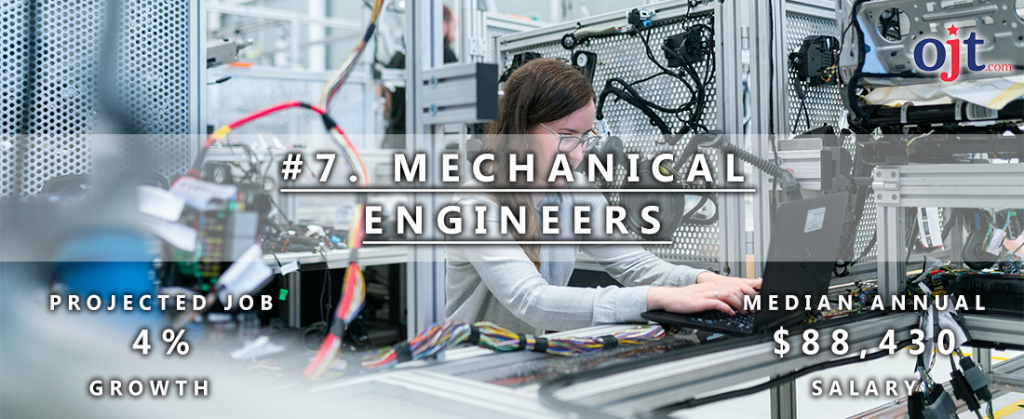

Mechanical Engineers research, design, develop, build, and test mechanical and thermal sensors and devices, including tools, engines, and machines. They analyze problems to see how mechanical and thermal devices might help solve a particular problem. As well as design or redesign mechanical and thermal devices or subsystems, using analysis and computer-aided design. Reading and understanding blueprints, schematics, and CAD files are extremely important in this role. The largest employer of mechanical engineers are engineering contractors.

Woodworkers manufacture a variety of products such as cabinets and furniture, using wood, veneers, and laminates. They often combine and incorporate different materials into wood. They must Prepare and set up machines and tooling for woodwork manufacturing and ensure the finished product meets design standards. Reading and understanding blueprints, schematics, and CAD files are extremely important in this role. The largest employer of woodworkers is furniture manufacturers.

Food & Tobacco Processing Workers operate equipment that mixes, cooks, or processes ingredients used in the manufacturing of food and tobacco products. This involves setting up, start, or load food or tobacco processing equipment. Checking, weighing, and mixing ingredients according to recipes. Recording batch data and performing quality checks on the final product. The largest employer of food & tobacco processing workers are food & tobacco manufacturers.

Industrial Production Managers oversee the daily operations of manufacturing and related plants. They coordinate, plan, and direct the activities used to create a wide range of goods, such as cars, computer equipment, or paper products. Ensuring that production stays on schedule and within budget. They also monitor a plant’s workers and programs to ensure they meet performance and safety requirements. As well as streamline the production process. The largest employer of industrial production managers is transportation equipment manufacturers.